10Q Paint Robot

The Future of Industrial Coating Application

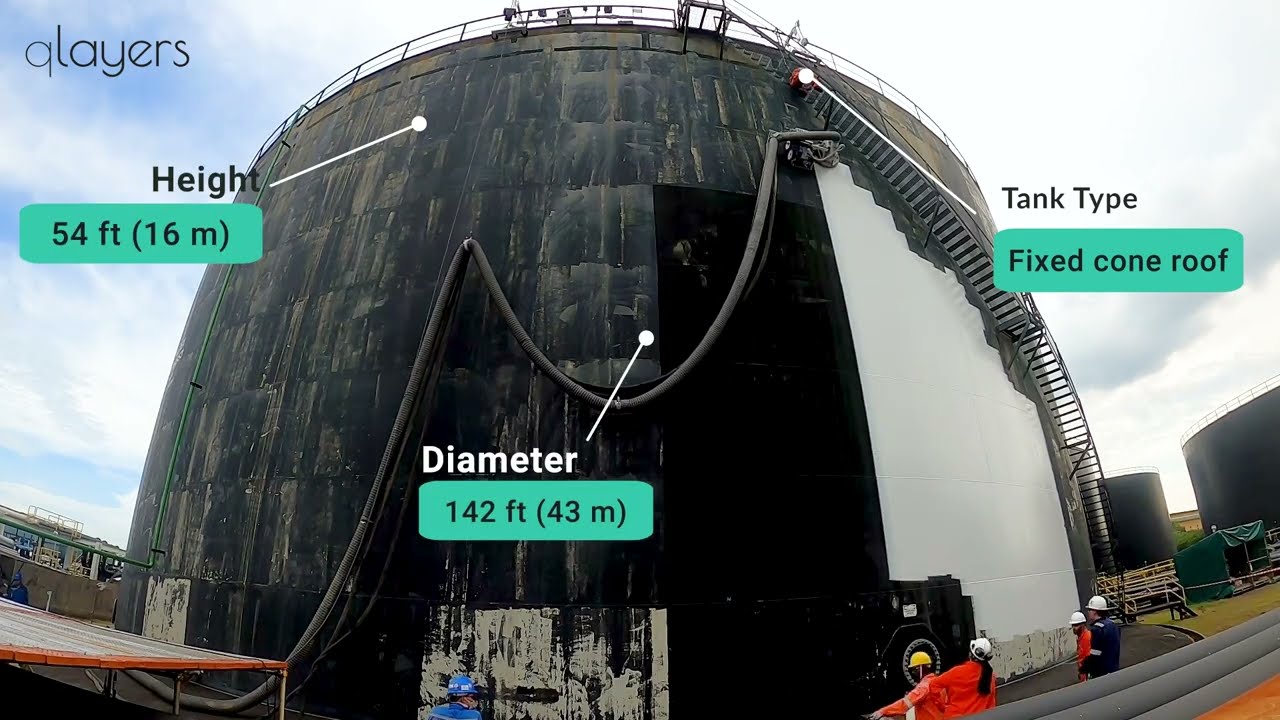

Qlayers' 10Q robot is the industry's first automated paint robot that transforms the manual method of coating large-scale storage tanks into a semi-automated, efficient, and safe process. Our innovative robotic solution enables clients to improve the efficiency and productivity of their coating projects while preserving the environment from overspray contamination.

During the application process, the workers can operate the robot from a safe distance on the ground using the user-friendly control system. Replacing manual work with the robotic solution reduces the number of working hours at dangerous heights by up to 80%, minimizing the risks of possible injuries caused by working on suspended platforms and scaffolding.

In addition, 10Q robots are equipped with Qlayers' patented spray shielding system that prevents overspray from being released into the air. Eliminating overspray is a great advantage of this technology which makes the spray coating process cleaner and safer for workers and the environment.

Since the first test pilot in late 2019, Qlayers' 10Q robots have been deployed in over 20 coating projects and demos at tank terminals in Europe, the UK, APAC and the USA.

| Specification Title | Specification Description |

|---|---|

|

Areas of Application

|

Storage tanks

|

|

Control of Process Flow

|

Automated quality control on coated areas of the tank.

|

|

Accuracy

|

Accurate layer thickness control and client reporting on key parameters in the application process

|

|

Cost

|

Cost competitive due to fewer man hours and automation.

|

|

Environment

|

Saving up to 20% paint. Virtually no overspray outside the spray shielding system.

|

|

Safety

|

Reduced working at dangerous heights by up to 80%.

|

|

Speed

|

Coating speed of >200m2/hour

|

|

Application Conditions

|

Good spray results up to a wind force of 4 Bft.

|

|

Automation

|

Semi autonomous, easy to operate, user friendly controller.

|

|

Maintenance

|

Daily and weekly maintenance to be done by coating contractor. Service and monthly and yearly maintenance to be done by Qlayers.

|

Reviews (7)

Sign up or log in to your explorer or platform subscription to get access to the reviews written about this technology.

The Technology Readiness Level (TRL) indicates the maturity level of novel technologies. Learn more about the TRL scale used by us.

[9/9]

Relative Business Impact

Sign up or log in to your explorer or higher plan to get access to all the 7 deployment references.

Last Deployment Year