IMS RCM – Reliability-Centered Maintenance

Setting the market standard in Integrity Management Software

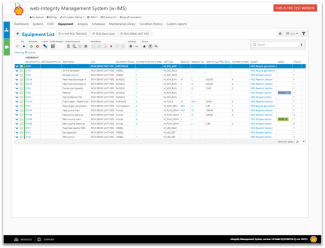

In close collaboration with Shell, Cenosco developed the web-based Integrity Management System (IMS). The IMS RCM Module is a tool to help with the optimization of an asset’s preventive maintenance plans. It supports the user to prioritize equipment based on risk. From the equipment’s risk profile, the best maintenance plan can be determined. This can be done manually or with library functions. This leads to safer assets with cost-effective maintenance plans and higher plant availability.

| Specification Title | Specification Description |

|---|---|

|

Areas of Application

|

Refineries, Terminals, Tank farms, Chemical plants, Process facilities, Pulp mills, Pipelines and Wells.

|

|

Certifications / licences

|

ISO 9001 | Microsoft Gold Partner | SAP Certified

|

|

Compliance

|

Auditable Events | W-IMS Platform (PEI)

|

|

Data Analysis

|

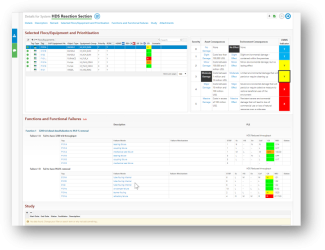

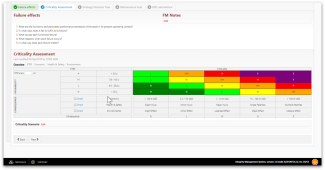

Evaluate the efficiency by calculating a Maintenance Efficiency Index factor | Identify risk by using the Failure Mode Effect Analyses and Criticality Analysis | Optimize maintenance plans by flexible task grouping

|

|

Hosting

|

Access your data anytime and anywhere with this web based solution. Available as Shared or Dedicated hosting as well as on premises – with state-of-the-art security systems.

|

|

Interface

|

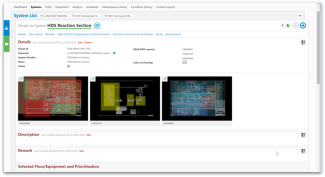

Interfaces to ERP systems (e.g. SAP, JDE, Maximo) via web API | Interface with AutoCAD drawings to define your RCM Systems.

|

|

Methodology

|

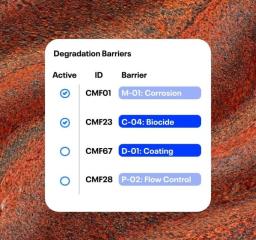

A structured decision support process is used to cost-effectively determine and document the optimum maintenance requirements of an asset | The classical RCM approach is streamlined to focus on the dominant (recurring) failure modes.

|

|

Reporting

|

Configurable dashboards, KPIs and reporting features, including 3D visualization.

|

|

Services

|

World class support desk with over 20 years of experience | 3 releases per year, with agile development | Training – onsite and open

|

|

Usability

|

Mainly moving (including rotating) equipment (where wear and tear can take place).

|

Reviews

Sign up or log in to your explorer or platform subscription to get access to the reviews written about this technology.

The Technology Readiness Level (TRL) indicates the maturity level of novel technologies. Learn more about the TRL scale used by us.

[9/9]

Relative Business Impact

Sign up or log in to your explorer or higher plan to get access to all the 10 deployment references.

Last Deployment Year