IPV3 - Economy Bidirectional Barrier Valve

Interventionless operation reduces Time, Cost, Risk and NPT

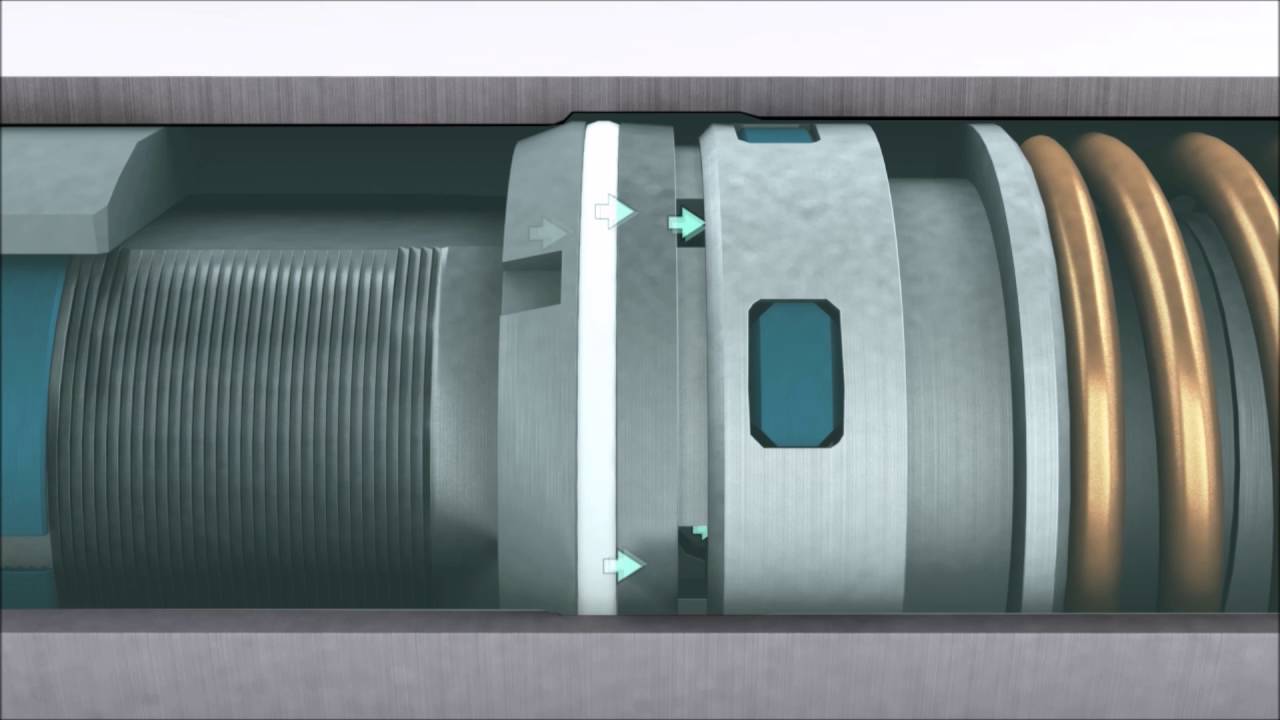

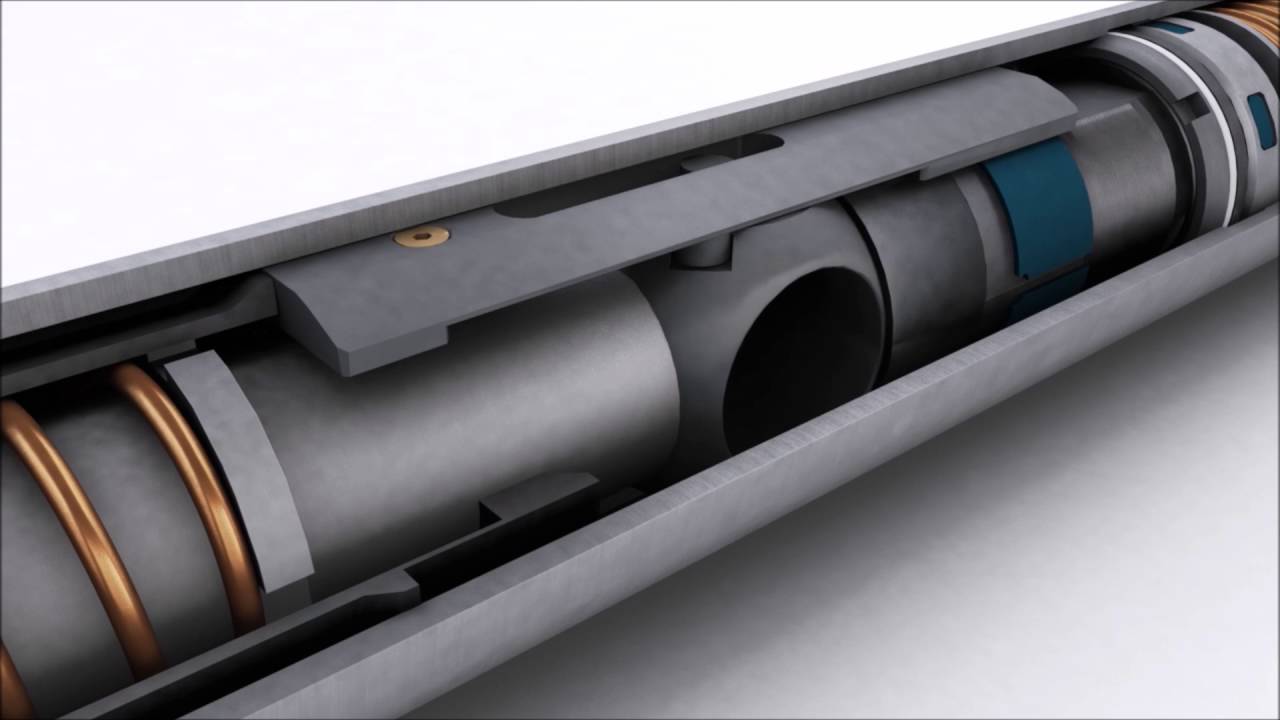

Building upon the outstanding reliability and success of IPV1, the Precision Oiltools IPV3 has evolved to provide bi-directional completion isolation barrier capability using the IPV1 platform. Utilising identical field proven sealing and patented equalising barrier valve technology whilst also incorporating the unique robust shear open reliability found in the IPV1 the IPV3 assures trouble-free intervention-less completion deployment.

As with the IPV1 the IPV3 does not require specialist offshore personnel for deployment whereby the barrier configuration is set to Operator specifications onshore. Should conditions dictate however, the barrier valve configuration may optionally be adjusted offshore if operations change prior to RIH.The IPV3 is deployed in the closed position providing a barrier for Packer Setting and Tubing Testing as well providing an in-flow completion barrier. An integrated circulation device may be deployed with the IPV3 allowing either forward or reverse circulation whilst RIH and offers remote close options.

| Specification Title | Specification Description |

|---|---|

|

Areas of Application

|

The IPV can seal & provide a barrier in extreme well conditions, and also in wells with high differential pressure across the barrier.

|

|

Safe operating

|

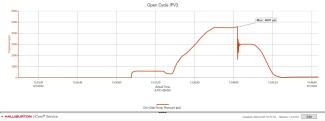

The IPV incorporates Precision Oiltools patented equalisation feature, before remotely opening the valve. This saves the Operator from a pressure surge during opening process which is integral to ESP completions.

|

|

Installation

|

Unlike other economy barrier valves, the IPV3 eliminates the need for wireline and leaves no debris in the well.

|

|

Capabilities

|

The IPV3 provides a bi-directional barrier which allows operators to: Remove the BOP and nipple down the X-Mas tree | Carry our tubing pressure tests | Set the production Packer

|

Reviews

Sign up or log in to your explorer or platform subscription to get access to the reviews written about this technology.

The Technology Readiness Level (TRL) indicates the maturity level of novel technologies. Learn more about the TRL scale used by us.

[9/9]

Relative Business Impact

Sign up or log in to your explorer or higher plan to get access to all the 1 deployment references.

Last Deployment Year