KC8 Carbon Capture Solutions

UNO MK3 Precipitating Potassium Absorption System

UNO MK 3 is a novel solvent absorption process initially invented within the Cooperative Research Centre for Greenhouse Gas Technologies (CO2CRC) and developed over the last decade by KC8. It is a catalytically enhanced precipitating solvent technology engineered to capture 90+ per cent of carbon dioxide (CO2) emissions from heavy industry sources such as cement plants, steel mills, chemical plants and CCGT power stations. The hard to abate industries. UNO MK 3 process is suitable for retrofitting to existing emission sources as well as for new build plants. The process is applicable to all CO2 sources, however due to its robust nature it has been particularly successful in high oxygen flue gases typical of Natural Gas Combined Cycle (NGCC) generators.

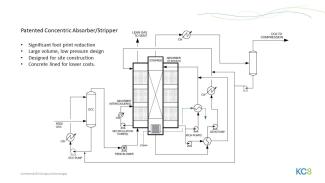

Potassium carbonate (K2CO3) has been used in solvent absorption processes in chemical industries for many years. The patented UNO MK 3 process provides a unique update to this established technology, making it highly efficient for CO2 capture at low pressure.

Plant testing of UNO MK 3 has been completed under real flue gas conditions at Hazelwood Power Station in the Latrobe Valley, Australia. These trials have successfully demonstrated the five key benefits of the UNO MK 3 process, namely:

- High CO2 capture rate over a wide pressure range

- Low energy of regeneration

- Low overall installation and operating cost

- Low volatility and environmental impact

- Multi-impurity capture and production of valuable by-products

Two commercial demonstration plants are now underway, in design. Both are to be installed in 2024, one in Australia on a cement kiln and one in the USA at the National Carbon Capture Center for the DoE.

| Specification Title | Specification Description |

|---|---|

|

Area of Application

|

Hard to abate industries - cement, steel, chemical, power generation.

|

|

Large Scale

|

Designed for high volume, lower pressure post combustion flue gas.

|

|

Easy to Install

|

Retrofit or green field. Minimal process impact, designed to operate at the flue gas/process gas outlet.

|

|

Small Dimensions

|

Low footprint for easy retrofit to existing plants. Unique absorber/stripper design for large scale applications.

|

|

Low Operating Costs

|

Next generation capture technology operating at $35-$40/t CO2 captured.

|

|

High Oxygen Tolerance

|

Solution is designed to operate in high O2 environments with out degradation.

|

Reviews

Sign up or log in to your explorer or platform subscription to get access to the reviews written about this technology.

The Technology Readiness Level (TRL) indicates the maturity level of novel technologies. Learn more about the TRL scale used by us.

[6/9]