M4 Mercury Monitoring System

Precise, accurate, and reliable

ISCT M4 volatile metals measurements systems are specifically designed to measure total gaseous mercury, arsenic and selenium in process gas streams such as natural gas, sour gas, fuel gas, LNG, LPG, butane, ethylene, propylene, hydrogen, carbon dioxide and Syngas. M4 systems and sample teams can be deployed from Texas, South Africa and New Zealand to support measurements projects for upstream, midstream and downstream assets globally. Services include Mercury Rumoval Unit performance evaluations, mercury mapping, distribution studies and total asset management.

| Specification Title | Specification Description |

|---|---|

|

Applicability

|

Mercury mapping and distribution studies | Mercury Removal Unit performance evaluations | Mercury measurements offshore well flow tests

|

|

Areas of Application

|

Upstream E&P, midstream NGL, downstream (refining & petrochemical)

|

|

ATEX certified

|

Class 1 Div 1 and ATEX rated.

|

|

Capabilities

|

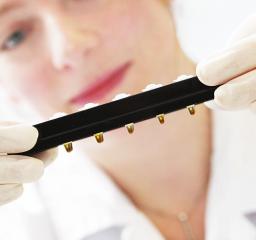

Solid sorbent traps for mercury, functional speciation mercury, DMHg, As and Se.

|

|

Cargo handling

|

Light weight mobile units travel with sample team via airplane or helicopter.

|

|

Compliance

|

ISO 6978, ASTM D6350, modified EPA 30B.

|

|

Heating

|

Heat traced sample line and sampling enclosure ~250˚F.

|

|

Measurement

|

Trace level mercury <10 nanograms EPA 1631.

|

|

Power

|

115 V 15 Amp

|

|

Safe operating

|

Designed for hazardous environments, redundant PSVs (insertion probe sample manifold and HSE).

|

Reviews

Sign up or log in to your explorer or platform subscription to get access to the reviews written about this technology.

The Technology Readiness Level (TRL) indicates the maturity level of novel technologies. Learn more about the TRL scale used by us.

[9/9]

Sign up or log in to your explorer or higher plan to get access to all the 2 deployment references.

Last Deployment Year