Superior Liquid Phase Droplet Coalescer

Maximising droplet coalescence in fouling service

The separation of two (2) immiscible liquids entrained in one another as separate phases, is normally driven by a density difference. In many cases, this takes place as the result of the gravity forces acting. Under ideal circumstances Stokes’ Law applies, which basically says: the larger the droplet, the faster it rises or settles. Maximising the droplet size through coalescence has therefore a direct positive impact on the overall efficiency that can be achieved by gravity separation.

Droplet dispersions

In many industrial processes, dispersions are created unintentionally. This typically happens when a multiphase fluid flow passes through a device that imposes a large shear on the fluids, such as (choke) valves, centrifugal pumps, etc. But also condensation of immiscible liquids and other physical phase changes can be found to form a tight dispersion. The droplets created are typically <30 micron and generally with a (very) narrow droplet size distribution. It means: difficult to separate!

Droplet coalescence

In order to obtain a bulk product or a waste stream with a low dispersed contamination, the dispersed phase needs to be reduced in volume. In many cases, however, the residence time required to separate the smallest droplets by gravity would be exceeding the time that is available in the process or any storage or intermediate tank. In this situation droplet coalescence is desired to shorten the gravity settling time.

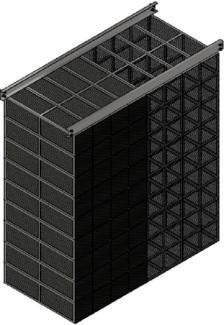

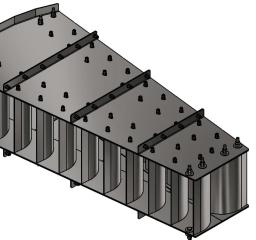

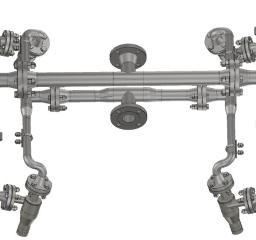

For that purpose, the Superior Liquid Phase Droplet Coalescer can be employed. The dispersed droplets only have to travel a very short vertical distance before they can agglomerate with others into a thin film layer at the next plate. Once the droplets have agglomerated with the film, the film will separate by gravity when it leaves the droplet coalescer. Different configurations of droplet coalescers are available to suit a wide range of process conditions and fluids. In clean service, the droplets can also be enlarged by a wide variety of Superior Liquid Phase Mesh Coalescers to maximise the overall separation efficiency. Note that dissolved components cannot be removed by coalescence; these would need to be transferred to a dispersed phase by mass transfer first.

| Specification Title | Specification Description |

|---|---|

|

Available sizes

|

Tailor-made to be compatible with vessel size and performance requirement.

|

|

MOC (SS)

|

304, 316, 321, 904

|

|

MOC (Duplex)

|

S31803, S32205, S32750

|

|

MOC (Alloys)

|

C276, 400, 625, 825

|

|

MOC (Other)

|

Other materials of construction upon request.

|

Reviews

Sign up or log in to your explorer or platform subscription to get access to the reviews written about this technology.

The Technology Readiness Level (TRL) indicates the maturity level of novel technologies. Learn more about the TRL scale used by us.

[9/9]