Torrgas Gasification Technology

Sustainable, carbon negative biofuels and green chemical products from biowaste

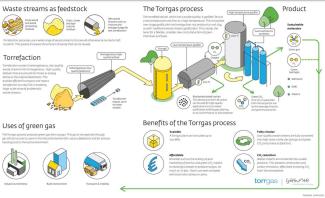

Our Innovative Solution: A patented two-stage gasification technology that uses torrefied biomass as the primary feedstock.

At the basis of our technology lies the use of torrefied biomass streams as a feedstock. This torrefied biomass is produced via torrefaction, a process that transforms various heterogeneous (waste) biomass streams into a uniform, coal-like product. This torrefied biomass serves as the foundation for stable and dependable operations. Using this torrefied material, Torrgas has developed a two-stage gasification concept. It consists of a low-temperature gasifier (LTG) and a high-temperature gasifier (HTG).

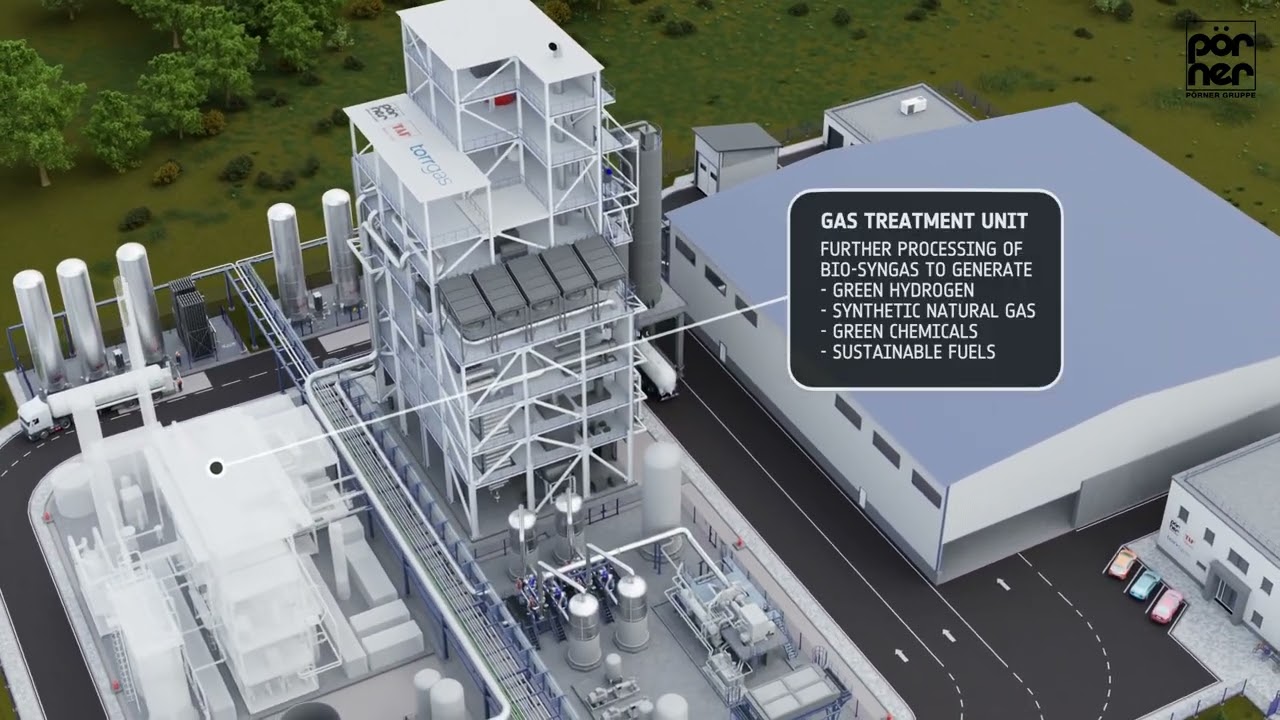

The LTG produces a gas fraction rich in hydrocarbons and a solid biochar fraction. The HTG cracks the hydrocarbon-rich gas, resulting in a chemical-grade syngas that's free from tar and nitrogen. This syngas is applicable in downstream processes, such as the synthesis of DME, Hydrogen, Methanol, SAF and SNG.

By separating the biochar in the LTG, we facilitate the use of a non-slagging HTG. This results in reduced CAPEX and operational expenditure (OPEX), as well as enhanced operational dependability.

The minerals in the torrefied biomass become concentrated in the biochar. This biochar can act as an environmentally friendly fertilizer or soil enhancer, creating a closed mineral cycle. By sequestering this biochar, the process becomes carbon-negative. Alternatively, the biochar can be used as a precursor for activated carbon (useful in applications like gas purification and water treatment), blast furnace coke, composite additives, and more.

| Specification Title | Specification Description |

|---|---|

|

2 stage reactor design

|

The 2 stage design allows for a non slagging gasifer that produces nitrogen and tar free syngas and biochar

|

|

Oxygen blown gasification

|

Production of high purity syngas

|

|

Value added by products

|

Biochar can be used in a variety of different sectors, such as the fertilizer, activated carbon and graphite market.

|

|

Homogeneous torrefied feedstock

|

Torrefied biomass usage results in a homogeneous feedstock which is much easier to handle and due to the increased energy density the transport costs are significantly lower compared to raw biomass

|

Reviews

Sign up or log in to your explorer or platform subscription to get access to the reviews written about this technology.

The Technology Readiness Level (TRL) indicates the maturity level of novel technologies. Learn more about the TRL scale used by us.

[7/9]

Relative Business Impact

Sign up or log in to your explorer or higher plan to get access to all the 2 deployment references.

Last Deployment Year