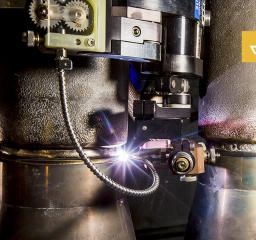

XXXL Metal Additive Manufacturing (WAAM)

Value the Future, Upgrade the Past: spare part production and repair

Guaranteed provides worldwide unique and fully integrated XXXL metal additive manufacturing production and repair services using WAAM (10m x 6m x5m and up to 20 tons) for a wide variety of metals (steel, stainless, aluminium, titanium, nickel based alloys, …) with a guarantee on performance, quality and lead time. This allows to avoid massive warehousing & logistic costs or to extend the lifetime of ageing installations. In both cases significant savings can be achieved with regards to cost, lead time, energy consumption and carbon footprint.

| Specification Title | Specification Description |

|---|---|

|

Implementation time

|

Fast prototyping to shorten development cycles for oil & gas components. WAAM limits downtime through reduced lead times and supply chain enhancements and offers the prospect of on-site manufacturing

|

|

Asset life extension

|

WAAM allows for lifetime extension by repair with reduced energy and carbon footprint, allows reproduction of obsolete parts and reduces warehouse stocks through on-demand printing

|

|

Cloud platform

|

WAAM can be coupled to an End-End workflow with ERP-systems and Digital Warehouse to allow on-demand 3D printing of spare parts

|

|

Maintenance

|

WAAM allows for lifetime extension by repair with reduced energy and carbon footprint. This ‘right to repair’ is supported by the European Parliament as part of the "New Circular Economy Action Plan".

|

|

Digitalisation

|

WAAM can be coupled to an End-End workflow with ERP-systems and Digital Warehouse to allow on-demand 3D printing of spare parts

|

|

Certifications / licences

|

Guaranteed QA/QC through process monitoring and in-line NDT compatible with e.g. DNV certification

|

Reviews

Sign up or log in to your explorer or platform subscription to get access to the reviews written about this technology.

The Technology Readiness Level (TRL) indicates the maturity level of novel technologies. Learn more about the TRL scale used by us.

[9/9]

Relative Business Impact

Sign up or log in to your explorer or higher plan to get access to all the 4 deployment references.

Last Deployment Year