Subsea TOFD

Time of Flight Diffraction - weld inspection

Defects in welds compromise the integrity and stability of offshore assets.

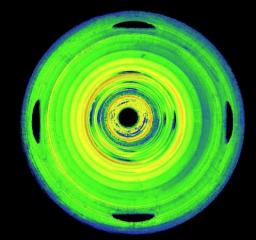

TOFD is an advanced non-destructive ultrasonic inspection method, which provides accurate sizing of defects quickly and reliably.

It was originally developed as a method to provide accurate monitoring and sizing of through-wall height of in-service discontinuities in the nuclear industry. TOFD allows for a incredible accurate data collection and measuring the critical through-wall size of weld defects.

TOFD normally goes hand in hand with the usage of other non-destructive testing solutions such as Phased Array.

| Specification Title | Specification Description |

|---|---|

|

Ultrasonic waves

|

Utilizes ultrasonic waves to detect faults.

|

|

Exact measurement of time

|

Relies on the exact measurement of time taken for ultrasonic waves to travel from the emiting probe to the diffracted waves received by probe.

|

|

Time of flight

|

Measuring this 'time of flight' gives and accurate size and location of the flaw.

|

|

Applications

|

Topside, Subsea and Welded Structures

|

Reviews

Sign up or log in to your explorer or platform subscription to get access to the reviews written about this technology.

The Technology Readiness Level (TRL) indicates the maturity level of novel technologies. Learn more about the TRL scale used by us.

[9/9]

Relative Business Impact

Sign up or log in to your explorer or higher plan to get access to all the 1 deployment references.

Last Deployment Year